Royston Handy Cap IP

Royston Handy Cap IP (with Integrated Primer)

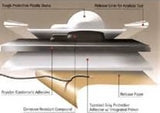

The Royston Handy Cap IP™ is a prefabricated assembly specially designed for cathodic protection leads to pipes and tanks. When pressed by hand into position over the anode lead wire weld, it forms a thick, highly resistant electrical insulation seal over the weld, the end of the lead wire and the surrounding area of the pipe or tank.

Handy Cap IP's are supplied complete with an elastomeric mastic having exceptional adhesive properties making it ready for immediate installation. The compound is firm enough to resist flow at all normal operating temperatures but soft enough to allow easy molding around welded areas. An integrated primer bonds the tough outer shell of the Handy Cap IP to the area metal and surrounding plant-applied coating, providing exceptional bonding without the costly application of liquid primer.

|

Construction |

Molded plastic cap filled with corrosion resistant compound on a base of thick elastomeric tape |

|

Overall Dimensions |

4 x 4 in |

|

Plastic Sheet (Serrated) Dimensions |

2-1/4 x 4 in |

|

Sheet Thickness |

10 mil |

|

Plastic Dome Diameter |

1-5/8 in |

|

Plastic Dome Height |

0.8 in |

|

Tape Thickness |

125 mil |

|

Weight |

2.1 + 0.4 oz |

|

Application Temperature |

-20 to + 120°F |

|

Service Temperature |

-40 to +185°F |

|

Shelf Life |

At least one year |

|

Packaging |

20 per Carton |

|

Shipping Weight |

5 lb |

Features

· A top plastic sheet formed with an igloo-shaped dome and entry tunnel for the lead wire.

· A special elastomeric compound in the plastic dome, which is firm enough to resist flow at all normally encountered application and operation temperatures, but soft enough to mold itself around and completely cover the irregular welded profile.

· On either side of the dome are a double row of parallel, flexibilizing serrations to assist with conforming around small diameter pipe.

· A base of Royston Tac-Tape, a black unbacked elastomeric tape with exceptional adhesive properties, for bonding firmly to the metal surface, when used with Roystons Roybond 747 primer.

Usage

Royston Handy Cap™ is easily applied and economical. It may be used on all anode lead wire and test wire weld areas. It is especially useful for welds on mill coated pipe where only a small part of the coating has been removed to permit installation of the thermite grounding connections. It is ideal for use in limited access situations, because it can be manipulated easily and applied at arm's length.

Application Procedure

Clean all mud, dirt, grease, oil and other contaminants from the metal surface and any part of the mill applied coating which is to be covered. Apply a coat of Royston RoyBond 747 Primer and allow to dry to an non-glossy appearance, which will take about 5 minutes, depending on humidity and temperature.

Remove the release paper from the bottom of the Royston Handy Cap. Bend the plastic sheet inward at the serrations when applying to small diameter pipe. Position and place the Handy Cap on the welded area with the tunnel over the lead wire.

Push the dome of the cap firmly into the weld area. Now lift the lead wire away from the pipe and squeeze the black rubber compound completely around and underneath the wire. Then push the lead wire back down on the pipe and press the elastomeric compound into firm contact with the pipe over the entire area.

No further protection is necessary when Royston Handy Cap covers the entire exposed metal area. Uncovered areas should be protected by applying tape or mastic, such as Royston Blue Max Pipe Line Tape CP or Royston Roskote Mastic.

When coating or wrapping the Royston Handy Cap, remove the narrow strips of plastic release film on the top of the cap. This will assure maximum protection by affecting a positive waterproof seal.